Metrology

Our processing equipment maintains excellent accuracy and repeatability however it is important that we continually measure the parts that we mold to ensure that they meet customer specifications.

To ensure that we always meet the requirements of your specifications our quality departments are equipped with measure and test equipment that provides them with the ability to accurately and comprehensively check the components and assemblies that we produce.

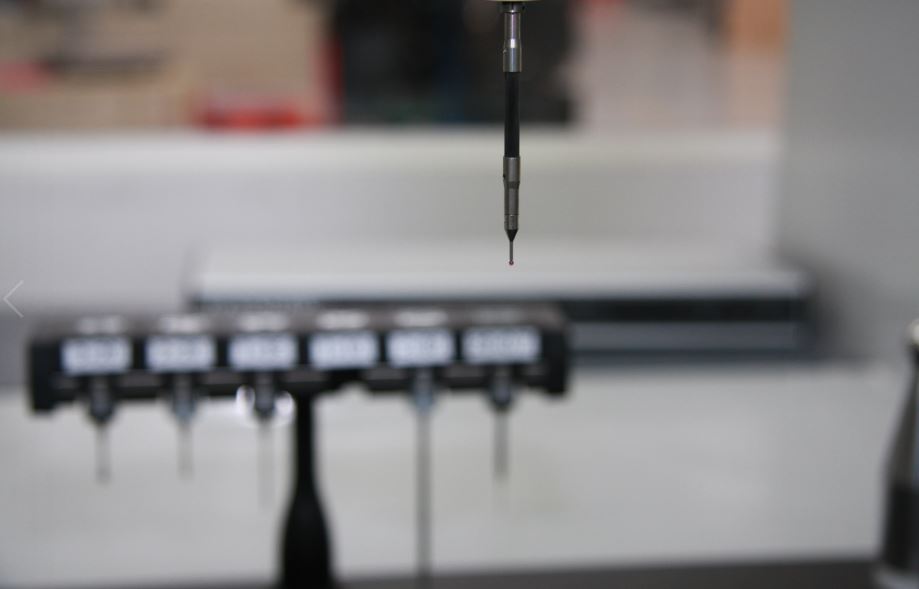

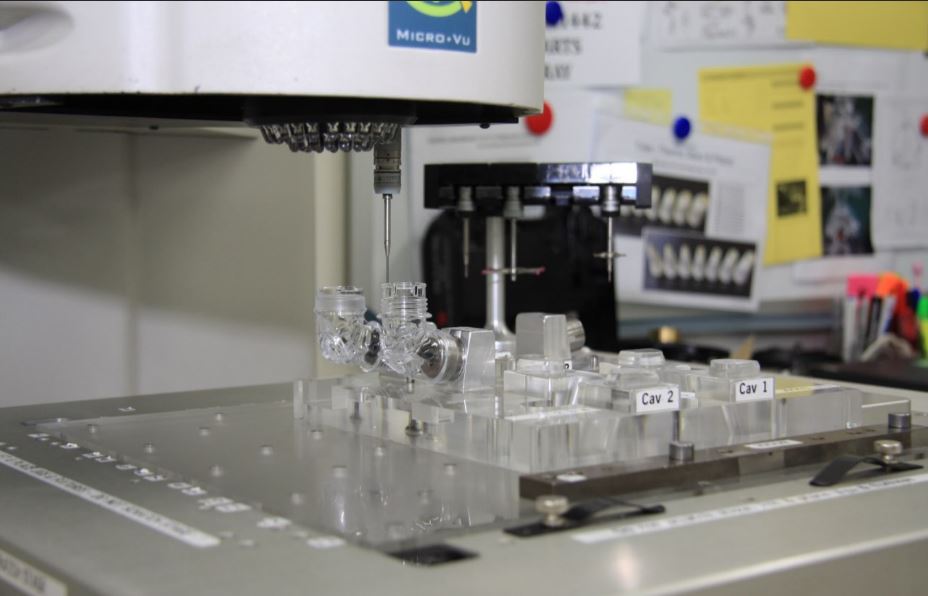

Our Micro-Vu and SmartScope both have non contact (optical) and contact measuring systems that feed data directly to analysis software that alerts the operator if there is a problem, or that a trend is forming that may result in a problem.

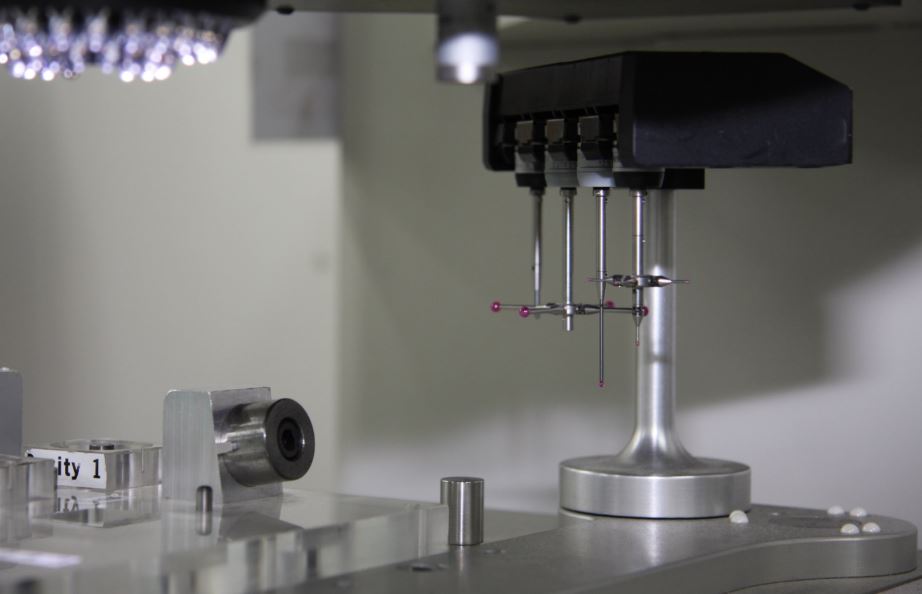

The CMM is a contact measuring machine that has the ability to compare the measurement results to the original part model. These are extremely accurate and versatile machines which are particularly useful when doing first article inspection (FAI).

Additionally we have Instron tensile and compression testing equipment and several bespoke devices for measuring air flow.

Of course we have the usual suite of hand operated measuring equipment, gauges and special purpose devices.

Many of our traditional products require leak testing so, with decades of experience, we are experts in this field.

Statistical Analysis

Our quality team routinely analyse the measurement and other data collected throughout production runs.

We have several software packages on hand for this purpose.

Data is analysed for trends that indicate impending problems.

Once we have a history of data for any product proprietary algorithms are used to determine upper and lower dimensional limits. These are used in addition to the upper and lower specification limits and are programmed into the monitoring software so that if there is a drift in process these limits will trigger a reaction plan ensuring that we maintain dimensions well within the customers specification.