QUALITY POLICY

W&S Plastics has been providing custom injection moulding and ancillary services to Australian companies for over 40 years. We continue to maintain our strong market position with an ongoing commitment to ensuring the satisfaction of our customers, employees, suppliers, shareholders and other stake holders through the supply of product and service that meets or exceeds their requirements. This will be achieved by maintaining the effectiveness of the Quality Management System, the periodic review of our quality objectives and by operating within the framework of all applicable regulatory requirements.

W&S Plastics has been providing custom injection moulding and ancillary services to Australian companies for over 40 years. We continue to maintain our strong market position with an ongoing commitment to ensuring the satisfaction of our customers, employees, suppliers, shareholders and other stake holders through the supply of product and service that meets or exceeds their requirements. This will be achieved by maintaining the effectiveness of the Quality Management System, the periodic review of our quality objectives and by operating within the framework of all applicable regulatory requirements.

We will continue to carefully and effectively pursue a Quality Management System based on

- OUR CUSTOMERS’ REQUIREMENTS

- CONTINUOUS IMPROVEMENT

- TRAINING AND EDUCATION

- COMMUNICATION

The Managing Director will ensure that the Quality Policy retains its suitability by regular reviews and that it is communicated and understood throughout W&S Plastics.

Andrew Wiseman

Director

Reviewed 2 April 2024

QUALITY MANAGEMENT SYSTEMS

Our quality management systems are the backbone of our manufacturing operations.

Sydney, Australia Quality Certification

Sydney, Australia holds certification to ISO 9001:2015 and ISO 13485:2016

Our ISO 9001 Quality System was upgraded to the 2015 revision and passed audit in July 2018.

We received our ISO 13485:2016 certification in October 2019.

This mature and robust quality management system has evolved with the changing requirements of industry and our business.

We have adopted the systems required to meet the stringent requirements of medical device component manufacture and assembly and have built these into our QMS and our culture.

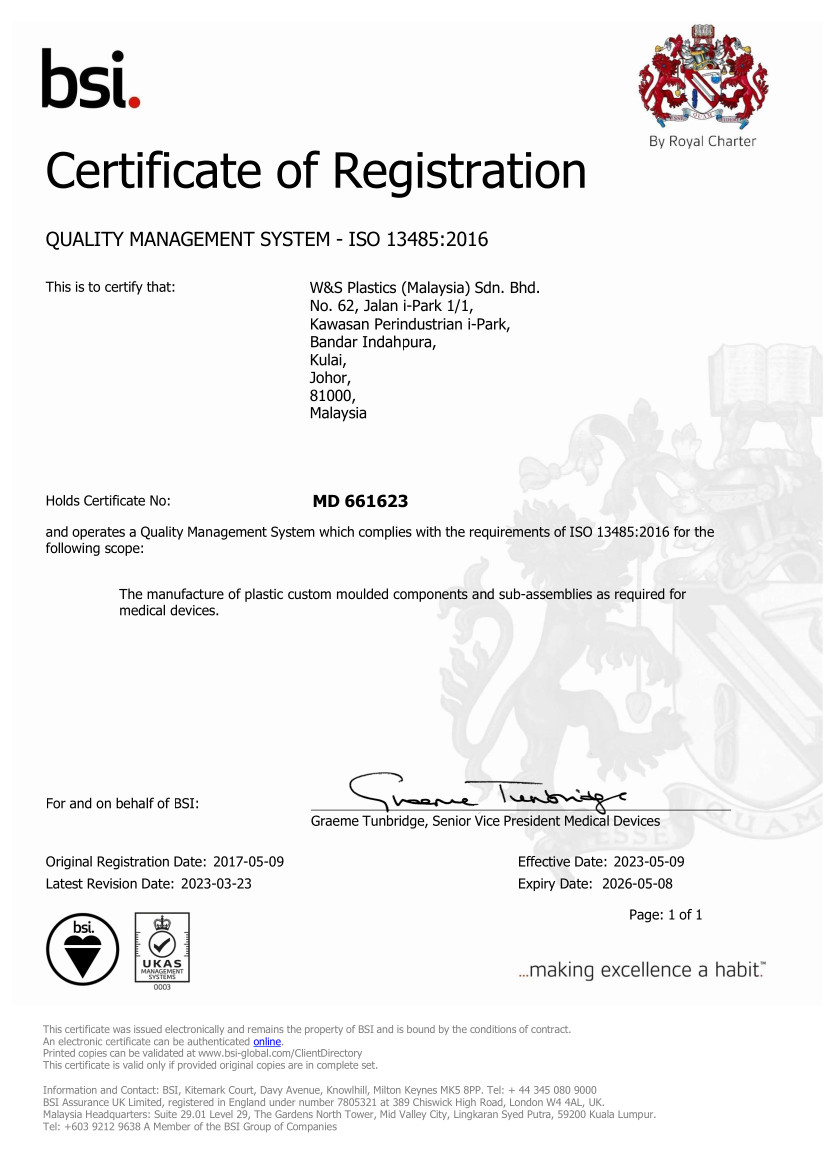

Johor, Malaysia Certification

Johor, Malaysia holds certification to ISO 9001:2015, ISO 13485:2016 and ISO14001:2015.

This plant was built specifically to suit the requirements of medical device manufacturing and incorporates everything required of ISO 13485:2016.

The climate controlled ISO Class 8 Cleanroom production area of our factory has been designed and built to meet the requirements of medical device component manufacture.

The Engel e factory, manufacturing execution system captures, stores and evaluates relevant information using the technology of industry 4.0 and the internet of things.

Both plants are well equipped to manufacture components for any industry no matter the level of complexity of their requirements.