Our customers benefit from the post molding processes that we offer which include:-

- Pad (tampon) printing

- Screen printing

- Hot foil printing

- Ultrasonic welding

- Sonic fastener insertion

- Vibration welding

- Laser cutting

- Laser engraving

- Assembly

- Packaging

More information for each of these follows.

Pad Printing

This involves the transfer of a ink from a ‘plate’ to the plastic component using a silicon pad.

This automated process is cost effective and has high output.

Images can be applied to textures and contoured surfaces.

We can apply single or multi color with the option of full color images using 6 process colors.

Artwork can be created or modified in house within hours of receipt.

The plates are made from aluminum backed Nylon or steel and are chemically etched with the image that is required. If the image is multi colored, a plate is required for each color.

W&S has plate making equipment in both our Sydney and Johor plants and can create a plate from a graphic in less than an hour. If you require help with your artwork, we can assist.

The YouTube clip below was posted by the supplier of our pad printing machines. It clearly explains the process.

Screen Printing

Screen printing is an ideal printing solution for many applications.

W&S Plastics has everything required to meet your screen printing requirements.

Artwork can be prepared from scratch or modified to suit within hours of receipt.

Assembly

W&S Plastics can manage all of your assembly requirements.

We can press, glue, screw or weld components together.

We have a comprehensive range of tests that we conduct to ensure the quality of your product:-

- electrical continuity

- bespoke electronic testing

- leak test

- air flow test

- flatness test

We can package sub assemblies for transport and further assembly or pack ready for retail.

Where there is sufficient requirement we manufacture automated assembly machines to reduce cost and increase output.

Hot Foil Printing

If your printing application requires a metallic, wood grain or some other specialty finish, Hot Foil Printing is the process to consider.

Gold and Silver gloss finishes on logos add “class” and impact.

Where security is paramount we can source specialty hologram foils manufactured by our supplier specifically and solely for us (you) which can be used to print tamper evident areas of your part or assembly.

As an example, we can print a security hologram onto thin tab which is glued or otherwise attached to two parts of a device casing. If the parts are separated the tab will break. A counterfeit replacement tab will not have the security hologram and therefore there will be clear evidence that the device has been compromised.

If you would like more information about this service please contact us.

Thermal transfer foils can be used which reveal information only under UV light ensuring accurate authentication of your product.

Ultrasonic Welding

Homogeneous welding of two plastic components can be achieved using ultrasonic welding.

W&S Plastics have many ultrasonic welding machines ranging from small to large.

This welding process is fast, inexpensive and extremely reliable. The resultant welded area is almost as strong as the plastic around it.

Ultrasonic welding is commonly used in the joining of toy components but at W&S Plastics we typically use it in the joining of components in electronic housings.

The same machines can also be used to insert nutserts, or brass components with internal threads, that are embedded within the plastic. Nutserts make the perfect thread in applications that will be disassembled regularly or where the integrity of the thread is critical.

It is vital that the design of the component include the details required for ultrasonic welding from the outset and our engineering team can assist.

We get many questions about how ultrasonic welding works so we have included some videos below for your information.

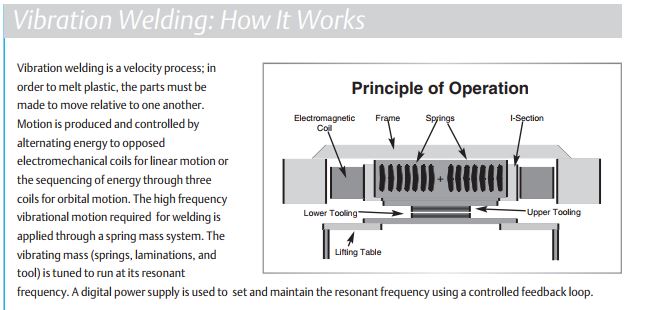

Vibration Welding

Vibration Welding Principle

The vibration method of assembly, when compared with ultrasonic assembly, is particularly advantageous for semi-crystalline resins such as acetal, nylon, thermoplastic polyester, polyethylene, and polypropylene, as well as PVC, cellulosics, thermoplastic rubber, and elastomers, filled and reinforced resins, and those exhibiting hygroscopic properties. Fillers such as glass, minerals, talc, and mica do not present a problem for the process, as long as the percentage is kept under 40%. Different grades of a material can be welded to each other.

Vibration welding replaces ultrasonic welding in many troublesome applications, since the ultrasonic process relies on transmitting energy through the part to the joint interface. For example, the ability to transmit weld energy is dependent upon the grade of material, as well as part shape and size, the percentage of regrind, the heat history of the plastic, as well as the color additives, melt flow index and filler content. Vibration welding is not subject to the same constraints, since energy is not transmitted through the part, but rather it is generated directly at the interface.

Our engineers have a great deal of experience with vibration welded components and can assist you with component design or advice on the correct the best method of welding for your application.